Home >> Vacuum Brazing Furnace >> High Vacuum Brazing Furnace For Alloy Brazing

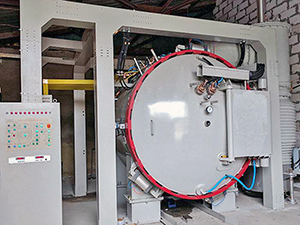

High Vacuum Brazing Furnace For Alloy Brazing

Min.Order Quantity: 1 Set/Sets High Vacuum Brazing Furnace For Alloy Brazing

Supply Ability: 2 Set/Sets per Month High Vacuum Brazing Furnace For Alloy Brazing

Payment Terms: L/C,T/T,

We can offers a complete service, working closely with you right from the initial design and engineering phase to final installation, providing turn-key solutions and technical assistance throughout the whole life cycle of your vacuum furnace.

Email: contact@vacfurnace.com

- Technical Parameters

- Product Details

- Send Inquiry

| Model | Temperature Uniform Size | MAX. Temperature | Ultimate Pressure | Pressure rising rate | Temperature Uniformity | Loading Capacity |

| RHVB-446H | 400*400*600mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 100Kg |

| RHVB-459H | 450*450*900mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 150Kg |

| RHVB-559H | 500*500*900mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 200Kg |

| RHVB-669H | 600*600*900mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 250Kg |

| RHVB-6612H | 600*600*1200mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 300Kg |

| RHVB-7712H | 700*700*1200mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 500Kg |

| RHVB-8812H | 800*800*1200mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 800Kg |

| RHVB-9920H | 900*900*2000mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 2000Kg |

| RHVB-101113H | 1000*1100*1300mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 2200Kg |

| RHVB-101024H | 1000*1000*2400mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 2600Kg |

| RHVB-121220H | 1200*1200*2000mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 3000Kg |

| RHVB-130945H | 1300*900*4500mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 3000Kg |

| RHVB-131245H | 1300*1200*4500mm | 1300℃ | 2*10-4Pa ~8*10-4Pa | 0.5Pa/h | ±5℃ | 4000Kg |

Your request will be answered within one working day.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)